Industrial and Commercial Air Filtration Solutions: Enhancing Air Quality in Factories and Workspaces

Factories, warehouses, and commercial facilities face unique air quality challenges due to dust, fumes, volatile organic compounds (VOCs), and other airborne contaminants generated by manufacturing processes, machinery, or high-traffic spaces. Air filtration systems, particularly industrial electrostatic air filters and commercial air purifiers, have become indispensable tools for addressing these challenges. This article explores the role of air filters in factories, the advantages of electrostatic filtration technology, and the benefits of commercial air purifiers in creating safer, cleaner, and more efficient workplaces.

The Importance of Air Filtration in Industrial Settings

Industrial facilities, such as factories, workshops, and production plants, often generate significant amounts of airborne pollutants. These include dust from material handling, welding fumes, chemical vapors, and microscopic particles that can pose health risks to workers or damage sensitive equipment. Poor indoor air quality in these settings can lead to respiratory issues, reduced productivity, and increased maintenance costs for machinery. According to studies, indoor pollutant levels in industrial environments can be two to five times higher than outdoor levels, making effective air filtration a top priority.

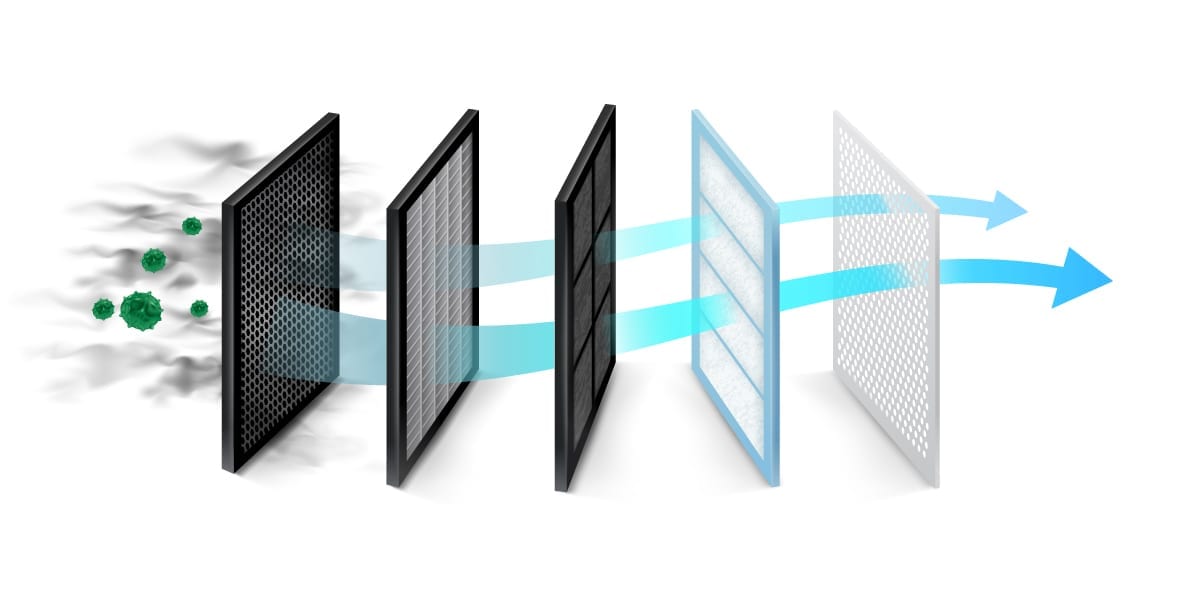

Air filters for factories are designed to remove solid particles, molecular pollutants, and hazardous aerosols from the air, creating a safer and more hygienic working environment. Unlike residential air purifiers, industrial air filtration systems are engineered to handle larger spaces and higher concentrations of contaminants. They often incorporate advanced technologies like High-Efficiency Particulate Air (HEPA) filters, activated carbon filters, and electrostatic precipitators to ensure comprehensive air purification. These systems not only protect workers but also improve product quality by reducing contamination risks in industries like food processing, pharmaceuticals, and electronics manufacturing.

Understanding Industrial Electrostatic Air Filters

Electrostatic air filters represent a highly efficient and sustainable solution for industrial air filtration. These filters work by generating a static electric charge as air passes through a woven or honeycomb filter media, typically made of synthetic materials like polypropylene. The charged media attracts and captures airborne particles such as dust, pollen, mold spores, and bacteria, much like a magnet. Unlike traditional passive filters, electrostatic filters actively enhance particle removal efficiency, making them ideal for environments with high dust loads or fine particulate matter.

One of the key advantages of industrial electrostatic air filters is their durability and reusability. Unlike disposable filters that require frequent replacement, electrostatic filters can be washed and reused, reducing long-term costs and environmental impact. For example, companies like LakeAir produce electrostatic filters with a lifespan of over 20 years, with 98.6% of their components being recyclable, significantly reducing landfill waste. These filters are constructed with robust materials like steel and aluminum, ensuring they withstand the demanding conditions of industrial settings.

Electrostatic precipitators (ESPs), a subset of electrostatic filtration technology, are particularly effective for industrial applications such as laser cutting, welding, and machining, where oil mists and fine particles are prevalent. ESPs use high-voltage charges to collect particles as small as 0.01 microns with up to 99% efficiency. Purified Air, a UK-based manufacturer, highlights the scalability and low maintenance of their ESP systems, which use metal components that can be easily cleaned rather than replaced.

However, electrostatic filters have limitations. Their Minimum Efficiency Reporting Value (MERV) ratings typically range from 1 to 4, making them less suitable for capturing ultra-fine particles in highly sensitive environments like hospitals or cleanrooms. For such applications, combining electrostatic filters with HEPA or ULPA filters may be necessary.

Read more: Preventive Maintenance vs. Emergency Service Call for HVAC: Which is Better?

Commercial Air Purifiers: Tailored Solutions for Diverse Environments

Commercial air purifiers are designed for a wide range of settings, including offices, restaurants, hospitals, schools, and retail spaces. These systems are typically larger and more powerful than residential units, capable of handling high volumes of air and addressing specific pollutants like smoke, odors, and allergens. Commercial air purifiers often integrate multiple filtration technologies, such as HEPA filters, activated carbon filters, and UV-C light, to provide comprehensive air purification.

HEPA filters, which capture 99.97% of particles as small as 0.3 microns, are a cornerstone of commercial air purifiers. They are highly effective against common contaminants like dust, pollen, and smoke, making them suitable for environments with high foot traffic or sensitive populations, such as hospitals and schools. Activated carbon filters complement HEPA filters by adsorbing odors, gases, and VOCs, which is particularly beneficial in settings like commercial kitchens or cannabis dispensaries.

For example, Camfil’s industrial air cleaners combine certified HEPA and molecular filtration to remove dust, odors, and airborne viruses in manufacturing plants, warehouses, and food production facilities. These systems are designed to supplement existing HVAC systems, reducing energy consumption while enhancing air quality. Similarly, HealthyAir® offers commercial air purifiers with patented eHEPA® technology, which combines electrostatic and HEPA filtration for superior performance in high-pollution environments like nail salons or welding shops.

In specialized settings like cigar lounges or vape shops, commercial air purifiers known as “smoke eaters” are used to manage heavy smoke and odor loads. These systems, such as the LakeAir LA1400-S or the MiracleAir CM-12-D, combine electrostatic filtration, HEPA filters, and significant carbon content (up to 22 pounds) to neutralize smoke and odors effectively.

Read more: Best Website to Buy Medical Equipment: Explore Top 5

Key Considerations for Choosing Industrial and Commercial Air Filters

Selecting the right air filtration system for a factory or commercial space requires careful consideration of several factors:

-

Room Size and Airflow Capacity: Industrial and commercial spaces often require systems with high Clean Air Delivery Rates (CADR) to handle large volumes of air. For instance, LakeAir’s industrial line offers units with airflow capacities ranging from 1,900 to 10,000 cubic feet per minute (CFM), suitable for spaces up to 50 feet by 50 feet.

-

Type of Contaminants: Different pollutants require specific filtration technologies. Electrostatic filters excel at capturing dust and larger particles, while HEPA filters are better for fine particulates like viruses or mold spores. Activated carbon filters are essential for odor and gas removal.

-

Maintenance Requirements: Electrostatic filters are low-maintenance and reusable, but they require regular cleaning to maintain efficiency. HEPA filters, while highly effective, need periodic replacement, which can increase operational costs.

-

Energy Efficiency: Modern air purifiers prioritize energy efficiency to reduce operational costs. Systems like the Euromate HF Industrial Air Cleaner provide powerful filtration (up to 5,000 m³/h) while maintaining energy-efficient operation, making them suitable for large industrial facilities.

-

Safety Features: In hazardous environments, such as those with flammable gases, explosion-proof motors or other safety features may be necessary. Industrial air purifiers are often designed with these considerations in mind.

-

Regulatory Compliance: Industrial and commercial air filtration systems must comply with standards like CE, ISO, or ASHRAE. For example, Camfil’s HEPA H14 filters are certified according to EN1822 standards, ensuring compliance for sensitive applications.

Benefits of Electrostatic and Commercial Air Purification Systems

The adoption of industrial electrostatic air filters and commercial air purifiers offers numerous benefits:

-

Improved Worker Health and Productivity: Clean air reduces the risk of respiratory illnesses and allergies, leading to fewer sick days and higher productivity.

-

Equipment Protection: By removing dust and corrosive gases, air filters extend the lifespan of machinery and reduce maintenance costs.

-

Environmental Sustainability: Reusable electrostatic filters minimize waste, and energy-efficient systems lower the carbon footprint of industrial operations.

-

Cost Savings: Permanent filters like those from NeverBuyAnotherFilter.com eliminate the need for frequent replacements, offering long-term savings.

-

Versatility: Modular and scalable systems, such as those from Purified Air, can be customized for various industries, from restaurants to heavy manufacturing.

Case Studies and Real-World Applications

Real-world applications highlight the effectiveness of these systems. For instance, Euromate’s HF Industrial Air Cleaner has been praised for improving air quality in casinos and factories, reducing employee complaints and enhancing workplace satisfaction. Similarly, Transocean, a global oil rig operator, uses LakeAir’s Maxum HEPA units to maintain clean air in harsh environments, demonstrating their durability and reliability.

In commercial settings, Camfil’s City M air purifiers have been deployed in schools to protect students and staff from airborne pathogens, achieving significant reductions in biological contaminants. These examples underscore the versatility and impact of advanced air filtration systems across diverse industries.

Conclusion

Industrial electrostatic air filters and commercial air purifiers play a vital role in maintaining high air quality in factories and commercial spaces. By leveraging technologies like electrostatic precipitation, HEPA filtration, and activated carbon, these systems address a wide range of pollutants, from dust and smoke to odors and viruses. When selecting a filtration system, businesses must consider factors like room size, contaminant type, and maintenance needs to ensure optimal performance. With benefits ranging from improved worker health to reduced environmental impact, investing in high-quality air filtration is a strategic decision for any industrial or commercial operation. As air quality regulations tighten and awareness of indoor pollution grows, these systems will continue to be essential tools for creating safer, cleaner, and more productive workplaces.